BISO 2D VARIO

BISO 2D VARIO 770 - 1560 COMBINE HEADER RANGE

The BISO 2D VARIO series of headers covers working widths from 7.7 m to 15.6 m. It is a typical representative of the BISO design school, i.e. the VARIO header with a powerful auger, with tip tilting and integrated side knifes. Of course, the hybrid frame cannot be missing at these working widths, and the reel from one piece up to the 1230 model is also interesting. It is a header for customers requiring a long service life, top quality of work and low operating costs. The target group is therefore professional farmers and, above all, contractors with powerful combine harvesters.

The BISO 2D920 VARIO header. The picture shows a slight tilt of the cutter bar "on the tip".

The 2D model series uses technologies that we have been using in the company for more than 10 years. The difference is that they have been put together into the right "package" based on experience from customers and from different markets. It is a combine header developed for all types of crops, for high and low crops, for harvesting at high speeds, but above all for customers who emphasize minimal grain loss on the cutter bar, high performance of the combine harvester and top operator comfort. That is, the rate of change of the harvested crop with the ability to harvest multiple strategies of a given crop.

The heart of this header is traditionally a high-performance auger. In this case, a pair of augers with a central console.

It wouldn't be possible without the hybrid frame

From the working width range (7.7-15.6m) it is clear that it would not be possible without the hybrid frame. The hybrid frame is the result of almost 20 years of development. The main load-bearing element is an aluminium profile combined with high-strength steel parts. It excels in practically zero deflection even with cutter bars with a width of 12m and more. History has shown that the limit for steel frames is 9 meters. Of course, it is also possible to produce a steel frame with a larger width, but its characteristic feature will be springing (deflection). This is very annoying from the point of view of the service life of the other components of the header, because the weight becomes the limit.

BISO 2D headers therefore excel in high strength and resistance to bending, which is a basic prerequisite for us to use with professional combines, where the owner expects to harvest 20 thousand hectares and more.

High-performance combine harvesters also require premium headers.

Tip tilt

The hybrid frame also includes a set of parts for attachment to an inclined conveyor of a combine harvester with two hydraulic cylinders for tilting the header "on the tip". While driving, the driver can change the angle of the cutter bar and, in the optimal case, literally touch the ground with the tips of their double fingers and thus achieve minimal losses during harvesting. Of course, crop lifters can be put on the cutter bar lodged growth. The drivers of BISO headers very often solve the partial lodging of the vegetation by correctly tilting the bar and, as they call it, by literally "shaving" the lodged vegetation even on undulating terrain.

The crop lifters can be deployed in 10 minutes. Their holder is on the BISO trolley. They mainly reduce the wear of the knife, which does not have to work so close to the ground when using them. When harvesting rapeseed and the VARIO table is extended, the header can be folded slightly backwards to make it easier for the fallen grains to be directed towards the auger. Thanks to the hybrid frame and the replaceable parts set, it is also possible to adapt an existing header from one combine brand to another. And that's a considerable operational advantage.

The basis of this premium header is the technology we have been using for more than 10 years. However, we have put everything together in the right package, which is the 2D VARIO.

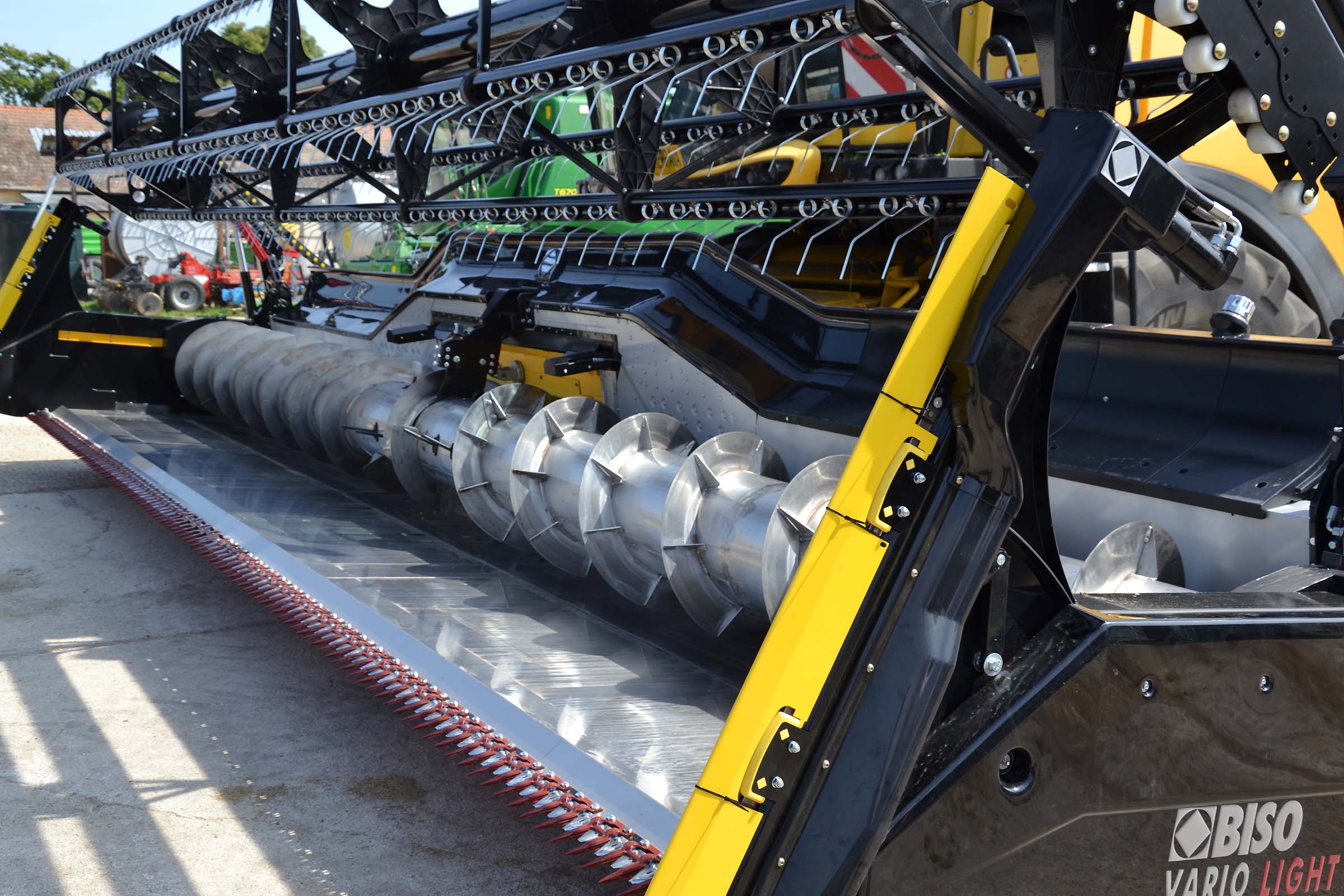

The BISO VARIO system

2D is a typical BISO VARIO header. The VARIO table therefore slides under the main frame of the header. Thanks to this patented solution, it is possible to extend the table by 70 cm, but what is very important is that it is possible to pull the VARIO and get the cutter bar to only 35 cm from the auger. Another typical feature of this design is the complete covering of the hydraulic cylinders for extension from below. The bottom of the bar in this premium series is Hardox. Plastic is not available.

The VARIO table is maintenance-free and can be smoothly retracted or extended by the driver while driving. Thanks to the new vario table brackets and the use of a new system of adjustable rollers, it is possible to better tune the movement of the vario table (the same solution as on 3D).

Current requirements of our customers? Quick change of settings for different crops and conditions, versatility, high operating comfort and service life. They take low harvest losses for granted.

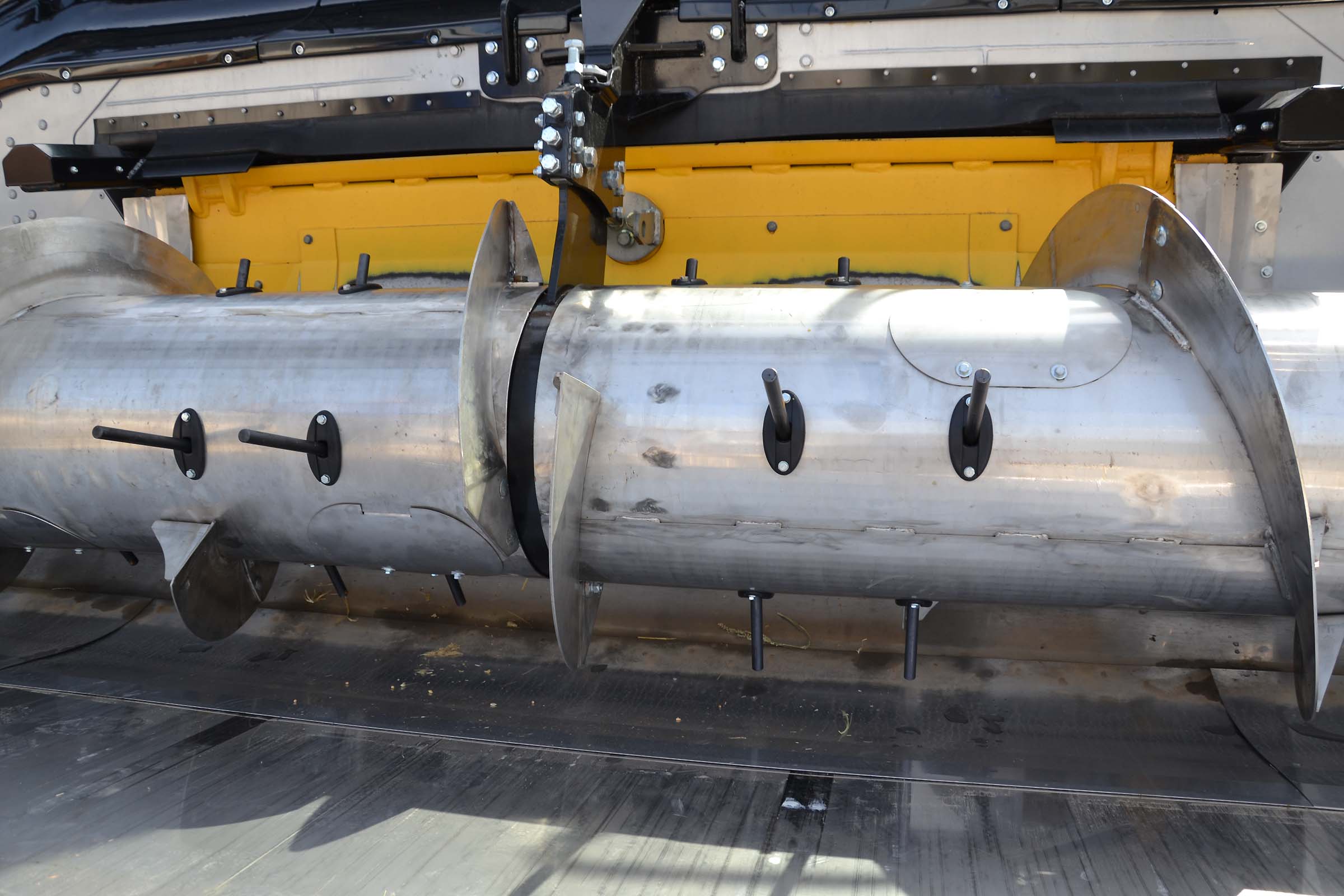

Split auger

With the exception of the 2D770, split augers with a central bracket are used in all cases. A solution that has also been tested in the field. The drives are chained on both sides and the load of the auger is, for example at the 12.3m cutter bar at the level of the knifes with a width of 6.15m. The gap between the auger and the bottom of the header is also very easy to adjust – with a ratchet wrench on both sides and on the centre bracket.

The auger and the VARIO table are the hallmarks of BISO combine headers.

In such demanding conditions, you can use the 2D VARIO to continuously change the distance between the knife and the auger, change the inclination of the bar, activate the side knifes whenever it is needed and reach where it is needed.

Reel with electrically tilted tines

The hydraulically driven reel has a hydraulic motor integrated into the central tube, as is common with BISO headers. It is typically for BISO to protect against winding and we supply electric adjustment of the inclination of the flexible tines of the reel as standard. Interestingly, up to a working width of 12.3m, the reel is one-piece. The protection against the contact of the flexible reel tines of the spring steel with the knife is traditionally solved in a simple and proven way – a roller track. This system is also functional when the vario and reel are extended in different ways.

The high-performance auger is the basis for the performance and versatility of this combine header.

Integrated side knifes

They are characteristic of BISO headers. When changing crops, the driver does not have to put on the side knifes and engage their drive. He only places the BISO side knifes in an upright position and removes the protective and safety cover. It is even possible to turn on the side knifes in the folded position or leave the dividers on and turn the side knifes on in the standing and tilted position as needed.

In the model range, we only use a hydraulic drive with a separate circuit with a hydraulic pump on the left rear side of the header frame (i.e. in the traditional place).

The 2D920 VARIO model already has a auger with side drives in the middle with the support, which has a major impact on the service life of all key components.

Copier

A standard BISO control box is used to control the 2D VARIO header. Already on the 2D920 model there are 4 copying skids and we use potentiometers from the combine harvester manufacturer. Therefore, the calibration of the combine is also used. The BISO control box is only used to switch on the side knifes, control the VARIO table and tilt it to the tip.

Central augers console in detail. The augers mounting system allows for quick adjustment of the gap between the auger and the bottom of the header if necessary.

2D920 – an attractive model

The 9.2m model appears to be very attractive with its specifications. Working widths of around 9 m are usually solved by a drive from one side, i.e. also a knife with a length of 9 m and a auger with a standing length. These drives are then already, but at the limit in terms of load. Based on the requirements of our customers and their recommendations, we have also fitted the 2D920 model with drives on both sides. This means that there are two knifes and a split auger in the header. Thus, the load on these key components is halved. For customers who buy a high-performance combine, but still want to stay with a working width of 9.2m, this model is a very interesting alternative for achieving high performance and at the same time the service life of the header.

With the stainless steel VARIO table, the side panels with knifes and, of course, with the divider also move. This solution is excellent for harvesting rapeseed.

What distinguishes the 2D Vario from the flagship 3D VARIOFLEX AIRi?

The 2D series does not use the FLEX module, i.e. suspension of the flexi cutter bar on parallelograms, air suspension of the knife and pressure sensing using patented sensors, i.e. intelligent functions. In many respects, the 2D series is much closer to the proven CropRanger model series (concept, electrics, hydraulics), which is based on the patented VARIO system, where the VARIO table slides under the main frame of the cutter bar and thus its extension is not restricted.

The consoles of the VARIO table are now guided by adjustable rollers.

So what characterizes the 2D series combine headers?

- VARIO table with extension of 700mm

- Hybrid frame (steel/aluminium combination)

- Tilting "on the tip"

- Header bottom cover of the Hardox

- Auger (split on most models) and made of stainless steel

- Hydraulically driven reel with integrated motor

- Winding protection

- Electric adjustment of the inclination of the reel tines

- Integrated side knifes with hydraulic drive

- Delivery with BISO ProfiSteer or ProfiTrailer trolleys

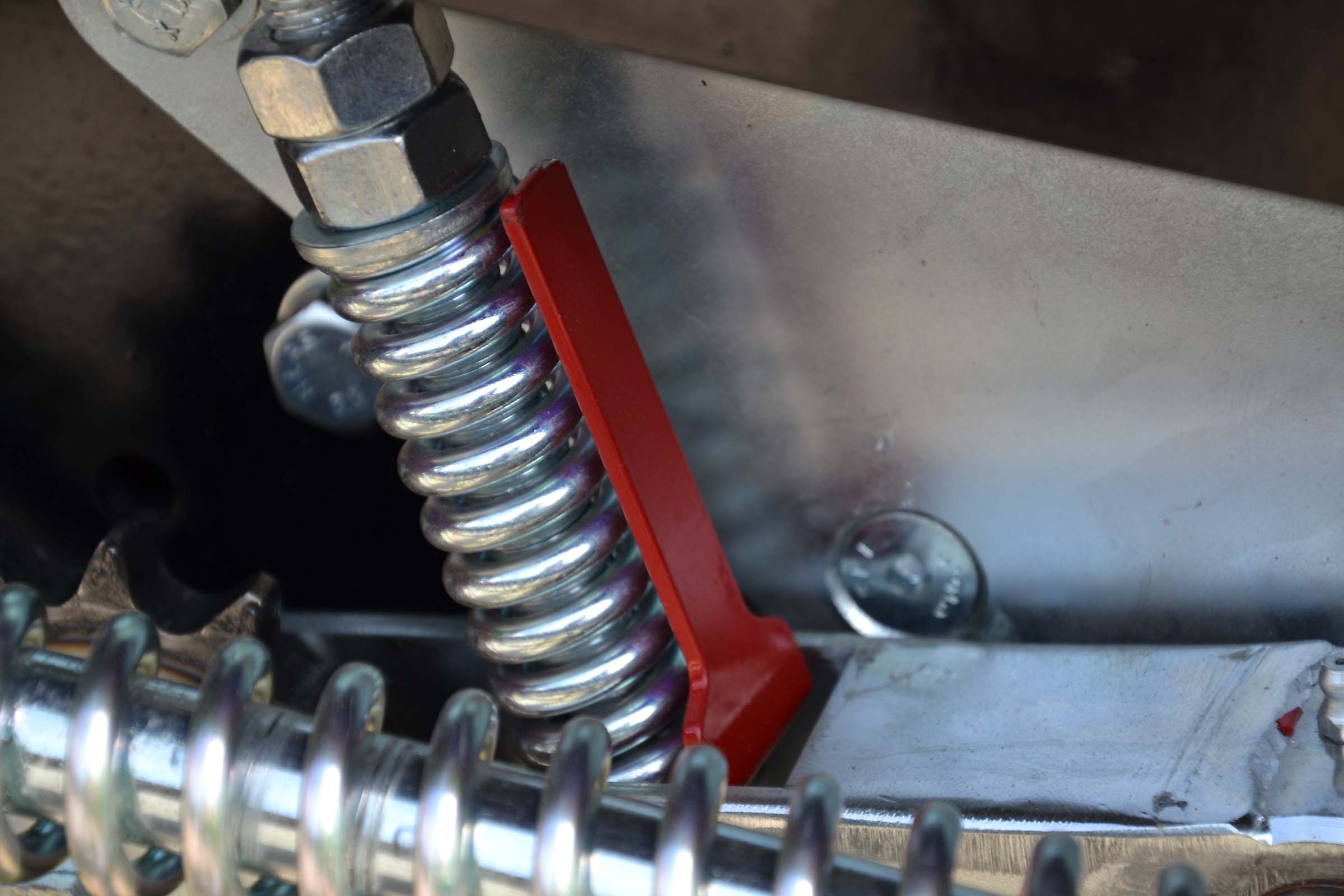

View of the side drives in the traditional BISO design. The knife is driven by a belt, the augers by a chain with automatic lubrication. Thanks to the double-sided drives, the load is halved. The picture shows drives with the VARIO table extended. The side knifes are hydraulically driven. In this generation, we have returned to welded steel sidewalls for easier repairs with less damage in operation.

Detail of the tensioning of the drive chain of the auger.

The bottom of the header is completely covered with hardox plates.

In this case, it is a SCHUMACHER kit, i.e. with double fingers and a Schumacher knife.

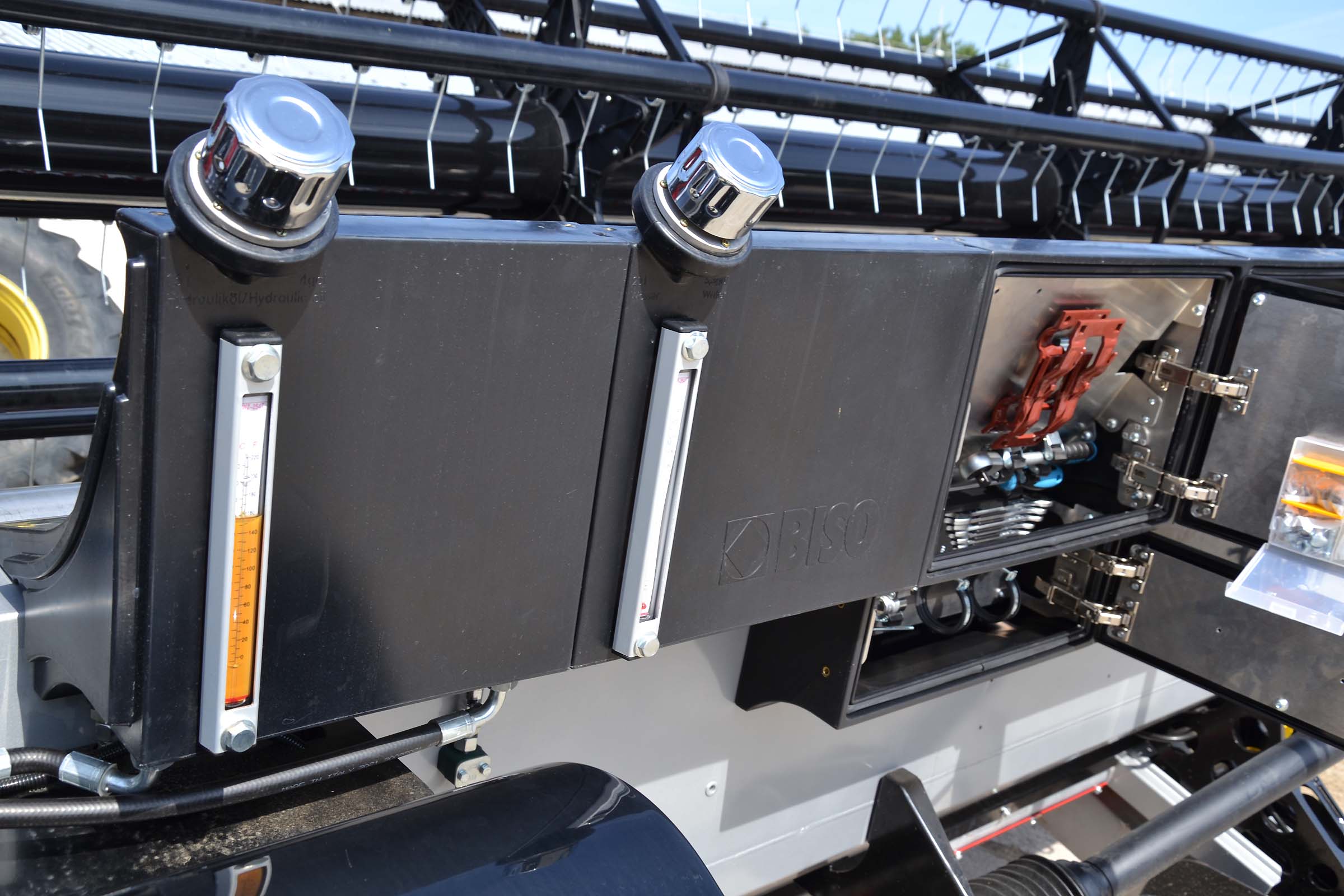

Tanks for hydraulic oils and water for hand washing are integrated into the grain splash guard.

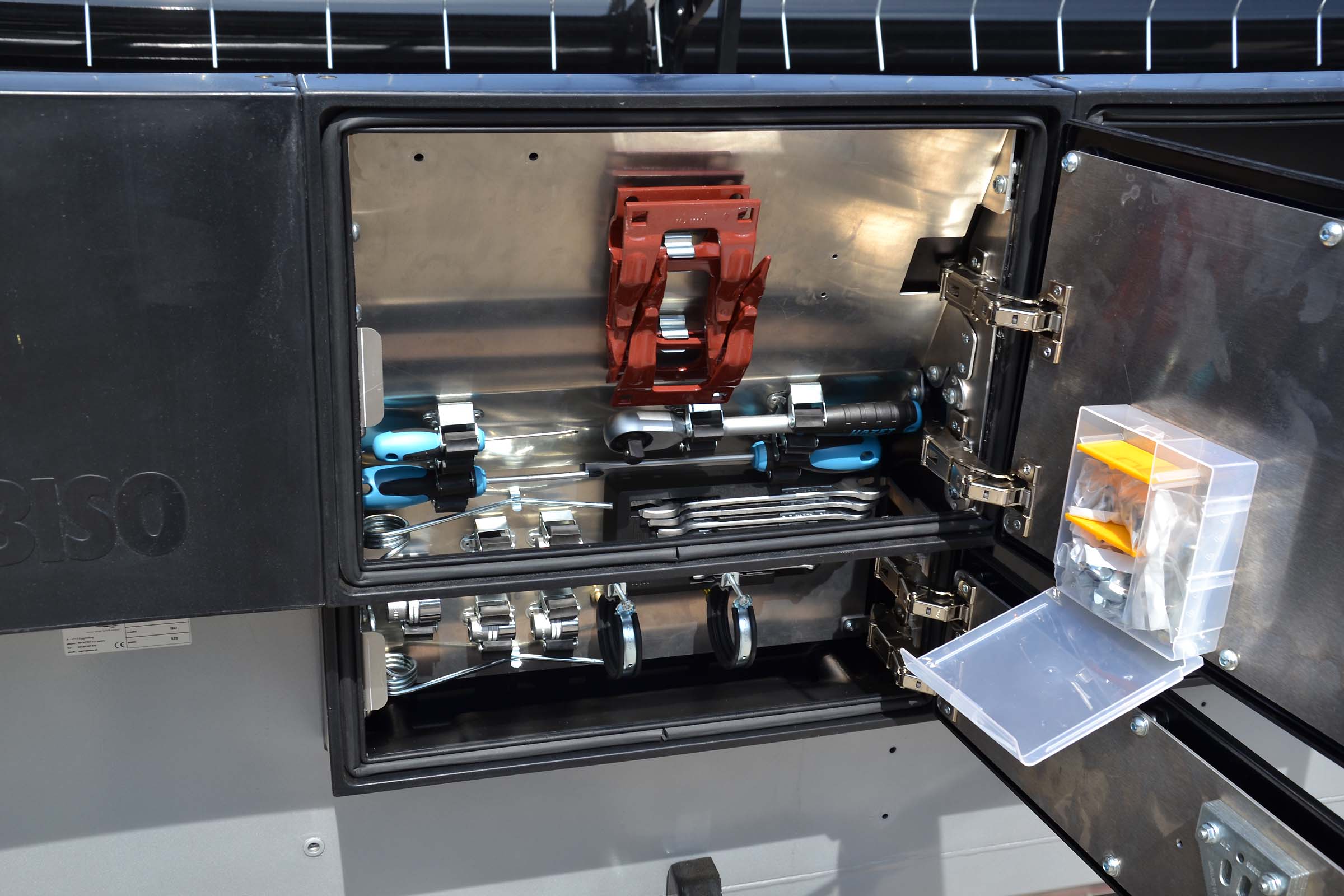

Tool box.

Fitting the cutter bar to the combine harvester is standard. All attachment points are on the left side, and on the right side there is only a second drive cardan thanks to the double-sided drives.

The precise fit of the header on the BISO ProfiSteer trolley is very important for the service life of the header. For smaller headers, we supply 4 beams, for larger ones 6.

Who is it for?

For high-performance combine harvesters, of which there are many on the market. The technology of 12+ combine headers is also implemented in the smallest 2D770 model, but especially in the 2D920 with double-sided drives and a split augers with a central console. It is a premium header for maximum harvesting efficiency, versatility, the ability to harvest a variety of crops in dry and wet conditions in top performance and quality of work.

The headers of this series are very serviceable and legible for crews with the highest possible level of operator comfort in this market segment.

More about the 2D VARIO cutter bars:

https://navigator.biso.eu/en/en-biso/harvesting-technics/biso-3d-varioflex-air-i/

Brochure in ENG version for download:

https://navigator.biso.eu/wp-content/uploads/2020/04/BISO-3D-VARIOFLEX-AIR-i-ENG.pdf

Other interesting articles: